|

Benefits of VSM |

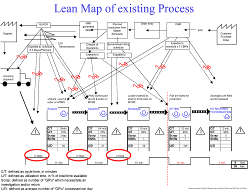

Value stream mapping |

|

Value Stream mapping is defining all the actions, both value added and non value added required to bring a product to the market place. Whether it is a tangible product or a service, every process can be broken down into: (1) the process from receiving the raw material until it is received by the customer and (2) the process of designing the product from concept to launch |

|

It helps you visualize your process. It helps you identify waste It helps tie together many of the concepts used in Lean. It show the linkages between information flow and material flow. If forms the basis for an implementation plan. |

|

Value stream & process mapping |

Process mapping |

|

Process maps and flow diagrams come in many forms. While VSM is an excellent tool, it may not be the right solution for your specific need. Many of the other flow tools that we use to help you better understand your process and deliver a solution to your particular issue are: 1) Process Charts: these charts analyze movement of people and materials with the goal of providing a view of operations, transportation, inspections, delays and storage points within your process. 2) Service Blueprinting: this tool lends itself to a focus on the customer and your interaction with the customer. 3) Service Process Matrix: this strategy forming tool helps you describe customer interaction in process design. |

|

Copyright Ň 2010 Lean 6 Sigma Solutions, LLC. All rights reserved. |

|

Quality is Not Expensive….. It is Priceless |